A fire pump is a part of a fire sprinkler system's water supply and can be powered by electric, diesel. The pump water source is either connected to the public underground water supply piping, or a static water source (e.g., tank, reservoir, lake). The pump provides water flow at a higher pressure to the sprinkler system risers and hose standpipes.

The fire pump starts when the pressure in the fire sprinkler system drops below a threshold. The sprinkler system pressure drops significantly when one or more fire sprinklers are exposed to heat above their design temperature, and opens, releasing water. Alternately, other fire hoses reels or other fire fighting connections are opened, causing a pressure drop in the fire fighting main.

Fire pumps are needed when the local municipal water system cannot provide sufficient pressure to meet the hydraulic design requirements of the fire sprinkler system. This usually occurs if the building is very tall, such as in high-rise buildings, or in systems that require a relatively high terminal pressure at the fire sprinkler in order to provide a large volume of water, such as in storage warehouses. Fire pumps are also needed if fire protection water supply is provided from a ground level water storage tank.

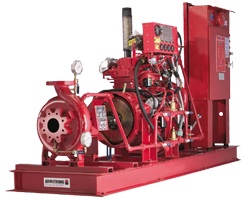

Types of pumps used for fire service include: horizontal split case, vertical split case, vertical inline, vertical turbine, and end suction.

Jockey pump is a small pump connected to a fire sprinkler system and is intended to maintain pressure in a fire protection piping system to an artificially high level so that the operation of a single fire sprinkler will cause a pressure drop which will be sensed by the fire pump automatic controller, causing the fire pump to start. The jockey pump is essentially a portion of the fire pump's control system.

Watania offer a high quality, FM-Approved and UL Listed fire pumps through one of the Top supplier in the world in field of Pump Manufacturing, ARMSTRONG.

Armstrong Has been manufacturing quality HVAC, fire protection and fluid flow equipment for residential, commercial and industrial applications for more than 75 years.

Armstrong pumps, controls, motors and parts are renowned for design efficiency, long service life and operating economy.

Using the most advanced engineering techniques, including solid modeling, finite element analysis and CAD.

Armstrong produces purpose-built products designed for optimal Solutions, minimized costs, and maximized value for fluid flow System requirements.

O-Sense

O-Sense