- 0

Approvals

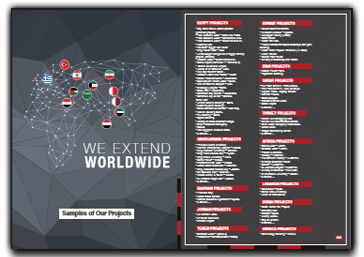

Watania for Trading & Engineering

Is representing a group of leading fire protection manufacturers as business partner suppliers to the Middle East, Mediterranean and Africa according to the territory area allowed for each brand.

Watania for Engineering & Contracting

Is specialized in providing the full engineering service for our fire Protection solutions starting from estimation, design, engineering up to full installation of the largest projects (fire fighting and fire alarm).

Watania for Modern Industries

Is a specialized factory for various types of fire fighting manual product (Cabinets, fire hoses 'racks and reels’, Accessories... etc) The first UL LISTED, OEM FIKE (USA) gaseous filling station in Egypt for filling and refilling of HFC-227ea "FM200" gas.

Fixed-System Proportioning EquipmentChemguard fixed-system proportioning equipment – bladder tanks, atmospheric foam-concentrate storage tanks, proportioners, and pump skids – reflect thier years of industry know-how, in-house design expertise, and exacting manufacturing. They also supply a precision foam-solution test kit to help fire-protection professionals determine the proportioning accuracy of mobile foam equipment, fixed foam systems, and portable foam equipment.Bladder TanksThe Chemguard Bladder Tank is one component in a balanced pressure foam proportioning system. It requires no external power, other than the water pressure to ensure correct operation. The vertical and horizontal bladder tanks are designed and constructed in accordance with the latest revisions to ASME code, Section VIII for unfired pressure vessels with a working pressure of 175 psi and tested to 1.3 times this pressure.

ProportionersChemguard designs, engineers, and manufactures a broad line of state-of-the-art proportioning devices: line proportioners (eductors), ratio-flow controllers, and the Ultra-Wide™ proportioner. Rugged, high-quality, and proven, these devices accurately and dependably proportion foam and water in a variety of applications.

|

Discharge DevicesChemguard's proven line of discharge devices meets the rigorous demands of industrial, marine, and municipal fire fighting, especially where high volumes of fire-fighting agents are required. Built to last in demanding applications, Chemguard equipment can discharge water or foam/water solutions at flow rates to 5,000 gallons per minute from a single location.Foam Chambers Data sheetDesigned to deliver foam directly onto the surface of flammable or combustible liquid and lessen submergence of the foam, foam chambers are installed on flammable liquid storage tanks just below the roof joint. Flow rates for these UL Listed, type 2 discharge devices (NFPA 11), can vary, depending on the application. Foam solution is supplied to a chamber from outside the hazard area, either from a fixed foam-storage and proportioning system or from a dry-pipe semi-fixed system that receives foam solution from a mobile foam apparatus. Upon entering the chamber the foam solution is expanded and then discharged against a deflector mounted inside the storage tank. The deflector (split or solid) directs the foam against the inside wall of the storage tank, reducing the agitation of the fuel. Chemguard foam chambers are suitable for use with hydrocarbons or polar solvent fuels, as well as with all low-expansion foam concentrates, proteins, and synthetics. Foam Makers Data sheetDesigned as air aspirating discharge devices, Chemguard foam makers are used principally for the protection of dikes, open floating-roof storage tanks, and rim seals, and where low-velocity foam streams are desired. Foam makers generally are installed in the line of a semi-fixed or fixed foam fire-protection system, mounted either horizontally or vertically. UL Listed, Chemguard's foam makers feature all-brass construction for use in harsh and corrosive environments. Foam maker air inlets are covered with stainless tell mesh, and the foam makers are supplied with standard NPT threaded inlets and outlets. Water Powered Oscillating Monitor Data sheetChemguard Water Powered Oscillating Monitors are designed to automatically discharge over a specific design area upon system activation. These are suitable for use in high risk areas such as tank farm facilities, aircraft hangars, offshore, refineries, chemical plants, and heliports. Monitor NozzlesAvailable for use with our full line of monitors, for water and foam solutions, Chemguard nozzles provide flow rates of 100 to 1,250 gallons per minute, with flows up to 5,000 gallons per minute possible on high-volume mobile/trailer units. Manufactured from corrosion-resistant brass or durable Chemlite™ anodized black aluminum, Chemguard nozzles are fully adjustable, from straight stream to full fog. Serrated teeth improve the water fog pattern and aid foaming AFFF solutions. Non-aspirating water fog nozzles are used for aqueous film-forming foam (AFFF) applications; aspirating nozzles are used for polar solvent fuels and fluoroprotein foam solutions. Chemguard’s master-stream monitor nozzles are offered in fixed-gallonage, adjustable-gallonage, automatic, and self-educting versions.

|

Our Partner Suppliers

O-Sense

O-Sense